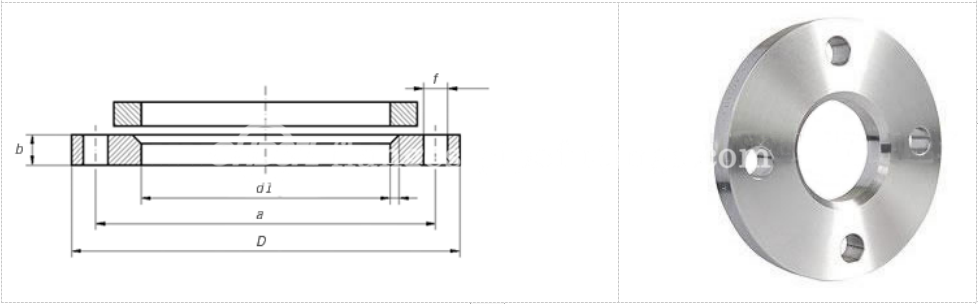

DIN 2642 PN10 FLANGE TSY MISY

FLANGE LAPPED

Ny refin'ny flange sy ny faobe eo ho eo

| Alemà standard flange DIN 2642 lapped flange;fanerena nominal 10 | |||||||||||

| Lose Flansche Vorschweißbördel Glatte Bunde DIN 2642 Nenndruck 10 | |||||||||||

| Brides tournantes: pression nominale 10 | |||||||||||

| sodina | Flange | Screws | lanja | ||||||||

| naoty | d1 | D | d6 | b | k | e | lavaka | tari-dresaka | d2 | Kg | |

| ISO | DIN | ||||||||||

| 15 | - | 20 | 95 | 22 | 14 | 65 | 3 | 4 | M 12 | 14 | 0,689 |

| 21,3 | - | 24 | |||||||||

| 20 | - | 25 | 105 | 28 | 14 | 75 | 3 | 4 | M 12 | 14 | 0,806 |

| 26,9 | - | 30 | |||||||||

| 25 | - | 30 | 115 | 33 | 16 | 85 | 4 | 4 | M 12 | 14 | 1,11 |

| 33,7 | - | 36 | |||||||||

| 32 | - | 38 | 140 | 42 | 16 | 100 | 4 | 4 | M 16 | 18 | 1,64 |

| 42,4 | - | 46 | |||||||||

| 40 | - | 44,5 | 150 | 50 | 16 | 110 | 4 | 4 | M 16 | 18 | 1,86 |

| 48,3 | - | 54 | |||||||||

| 50 | - | 57 | 165 | 62 | 16 | 125 | 5 | 4 | M 16 | 18 | 2,20 |

| 60,3 | - | 65 | |||||||||

| 65 | 76,1 | - | 185 | 81 | 16 | 145 | 5 | 4 | M 16 | 18 | 2,62 |

| 80 | 88,9 | - | 200 | 94 | 18 | 160 | 5 | 8 | M 16 | 18 | 3,32 |

| 100 | - | 108 | 220 | 113 | 18 | 180 | 5 | 8 | M 16 | 18 | 3,67 |

| 114,3 | - | 119 | |||||||||

| 125 | - | 133 | 250 | 138 | 18 | 210 | 5 | 8 | M 16 | 18 | 4,54 |

| 139,7 | - | 145 | |||||||||

| 150 | - | 159 | 285 | 164 | 18 | 240 | 5 | 8 | M 20 | 22 | 5,60 |

| 168,3 | - | 173 | |||||||||

| 200 | 219,1 | - | 340 | 225 | 20 | 295 | 5 | 8 | M 20 | 22 | 7,46 |

| 250 | - | 267 | 395 | 273 | 22 | 350 | 5 | 12 | M 20 | 22 | 10,30 |

| 273 | - | 279 | |||||||||

| 300 | 323,9 | - | 445 | 329 | 26 | 400 | 5 | 12 | M 20 | 22 | 14.00 |

| 350 | 355,6 | - | 505 | 362 | 28 | 460 | 6 | 16 | M 20 | 22 | 18,50 |

| - | 368 | 374 | |||||||||

| 400 | 406,4 | - | 565 | 413 | 32 | 515 | 6 | 16 | M 24 | 26 | 25.00 |

| - | 419 | 426 | |||||||||

| (450) | 457 | - | 615 | 467 | 38 | 565 | 6 | 20 | M 24 | 26 | 30,60 |

| 500 | 508 | - | 670 | 517 | 38 | 620 | 6 | 20 | M 24 | 26 | 37.00 |

| 600 | 610 | - | 780 | 618 | 44 | 725 | 7 | 20 | M 27 | 30 | 56,30 |

| 700 | 711 | - | 895 | 721 | 50 | 840 | 7 | 24 | M 27 | 30 | 80,40 |

| 800 | 813 | - | 1015 | 824 | 56 | 950 | 7 | 24 | M 30 | 33 | 113,20 |

FANAMARIHANA:

1. Miatrika araka ny DIN 2526

tarehy fisaka:

Form A, endrika tsy misy fepetra

Endrika B, Face Rz=160, vita amin'ny milina (tsy malama noho ny 40µm)

Natsangana tarehy:

Endrika C, Face Rz=160, vita amin'ny milina (tsy malama noho ny 40µm)

Endrika D, Face Rz=40, milina

Endrika E, Face Rz=16, vita amin'ny milina

2. Ny lela sy ny groove araka ny DIN 2512

endrika F, lela

Fomba N, Groove

3. Lehilahy sy vavy araka ny DIN 2513, DIN 2514

Endrika V13, V14, Lahy

Form R13, R16, Vehivavy

4. Chemfering ho an'ny diaphragm-weld packings, PN64-PN400, araka ny DIN 2695

5. Mifanatrika amin'ny tonon-taolana miendrika family, PN64-PN400, araka ny DIN 2696

Fahaiza-mamokatra sy antsipiriany momba ny fividianana

1. Famatsiana Flange Dimension DN15 – DN2000 (1/2″ – 80″), Forged Flange.

2. Material Carbon Steel: RST37.2, C22.8, S235JR, ST37, P235GH, P245GH, P250GH, ASTM A105

3. Material Stainless Steel: ASTM A182 F304, F304L, F316, F316L, F321 sns.

4. Flanges Anti Rust: Anti Rust menaka, Loko mainty, loko mavo coating, mafana natsofoka tafo, mangatsiaka Galvanized sns.

5. Vola isam-bolana: 3000 taonina isam-bolana.

6. Delivery fepetra: CIF, CFR, FOB, EXW.

7. Fepetra fandoavam-bola: Wire Transfer (T / T), L / C tsy azo ivalozana amin'ny fahitana sns.

8. Fatiantoka kely indrindra: 1Ton na 100Pcs.

9. antoka kalitao: EN10204 3.1 Certificate, Certificate Mill, Inspection Antoko fahatelo, Serivisy fanoloana maimaim-poana.

10. Mitadiava zavatra takiana bebe kokoa amin'ny tsenan'ny Flange.